Agricultural Literacy Curriculum Matrix

Lesson Plan

Mystery Juice (Grades 6-8)

Grade Level

Purpose

Using an inquiry approach, students will develop an investigation to determine the difference between two juices. Food safety will be discussed in relation to the results of the investigations. Students will have the opportunity to discover how pasteurization reduces the number of microorganisms in a food such as juice. Grades 6-8

Estimated Time

Materials Needed

For the Class

- Pasteurized and unpasteurized juice (1 to 2 cups of each) in clear containers

For Each Team

- 2 to 4 sterile Petri dishes with nutrient agar and covers

- Sterile swabs

- Parafilm to seal dishes

- Safety gloves

Advance Preparation

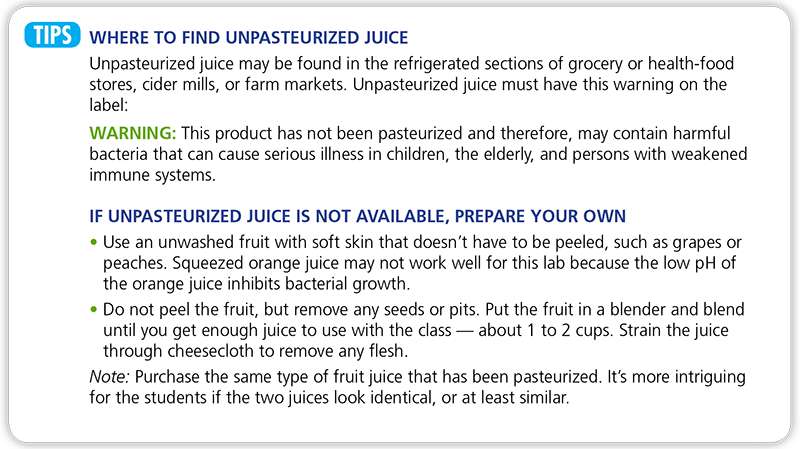

- Do some juice “scouting” and find pasteurized and unpasteurized juice made from the same type of fruit. (If available, unpasteurized apple cider and pasteurized apple juice work well.)

- If unpasteurized juice is not available, you can prepare your own (see below).

- Use 2 pint jars or other clear containers that have lids. Wash and sterilize the jars and lids (see page 8).

- Mark one container “A,” and pour in 1 to 2 cups of the unpasteurized juice. Close the lid.

- Mark the other container “B,” and pour in 1 to 2 cups of the pasteurized juice. Close the lid.

- Keep the containers closed and refrigerated until class time.

- On activity day, place the equipment that students might use on a lab table.

Vocabulary

irradiation: the process in which ionizing energy is used to kill foodborne pathogens

pasteurize: a process of partial sterilization involving heat treatment to kill bacteria and make a product safe for consumption and to improve its keeping quality

Did You Know?

- More than 1,000 different types of food are pasteurized.

Background Agricultural Connections

Students will discover the importance of pasteurization in relation to food safety. They will understand the importance of reading product labels that indicate whether or not a food has been pasteurized. Food safety plays a major role throughout food processing.

Pasteurization

Pasteurization is the process of using heat or irradiation to destroy microorganisms that could cause disease. Today’s modern dairy farms may house up to 5,000 cows each. All the farm’s milk is pooled, so if one cow is sick, there is a possibility to contaminate all the milk. That’s why milk is pasteurized.

Milk was one of the first products to be pasteurized on a broad scale. In addition to dairy products, other pasteurized foods include fruit juices, chicken, beef, and spices.

One challenge scientists faced was trying to figure out how to pasteurize an egg without cooking it. The solution was to heat the eggs up slowly to 135° F (57° C) and maintain that temperature for 1 hour and 15 minutes. This time/temperature relationship inactivates the bacteria while keeping the eggs fluid.

Louis Pasteur (1822–1895), a chemist, was actually trying to prevent spoilage in wine and beer when he discovered pasteurization. Pasteurization was applied first in wine preservation. When milk producers adopted the process, it reduced foodborne illness substantially. You never know where science will lead you!

Traditional pasteurization is achieved by exposing foods to heat for a certain length of time. Bacteria are very heat-sensitive, and the higher the temperature, the quicker they can be inactivated. Using higher heat takes less time to kill pathogenic bacteria, whereas using lower heat takes more time.

Irradiation

Irradiation is the process in which ionizing energy is used to kill foodborne pathogens. During irradiation, an intense pulse of energy is emitted, either from a gamma radiation source like Cobalt 60 or from an electrical source like an electron beam accelerator. The energy penetrates the food and destroys any bacteria.

Irradiation damages the microbe’s DNA. Unless it can repair the damage, the microbe will die when it grows and tries to duplicate itself.

Ultra High Pressure (UHP) Treatment

UHP is a newer process that some food producers use for killing harmful bacteria in foods that contain water. This process destroys bacteria without the use of high temperatures or chemical additives. Thus, foods such as juices, salsas, cold cuts, and other moist foods are made safer while the vitamins, flavor, and freshness of the foods are maintained.

Using specially designed equipment, the food is subjected to 50,000 to 100,000 pounds of pressure per square inch. This ultra high pressure is maintained from 30 seconds to a few minutes, depending on the food. The ultra high pressure interferes with the metabolism and structure of bacteria and destroys these living cells without altering the basic composition of the food.

Important Note: Despite pasteurization, irradiation, and ultra high pressure (UHP) treatment, food can still become contaminated if the basic rules of food safety are not followed all along the Farm-to-Table Continuum. It’s important to always follow the 4 Cs of Food Safety: Clean, Cook, Chill, and Combat Cross-Contamination (Separate).

Transportation

The 4 Cs of Food Safety play a very prominent role during transportation. Keeping food safe and in good condition as it’s shipped across the country or around the world is critical. There are many steps to shipping food safely and there’s science behind each step.

- The cold chain has to be maintained throughout the loading process, in transit, and during receiving.

- The food is cleaned and precooled as it comes from the field or plant. The cooling extends product life by reducing field heat, rate of ripening, loss of moisture, rate of respiration, and the spread of decay.

- Proper packaging is selected for the product. The shipping container is cleaned and properly loaded, making sure that the boxes are stacked tightly to lock in the cold during transit.

- Proper temperature control can be tracked by satellites. Refrigerated containers usually have equipment that automatically records refrigeration system functions and the air temperature inside the container. This information provides a detailed record of refrigeration system performance throughout the trip.

- Food is properly stored and cooled at the warehouse.

Science and our Food Supply Modules

This lesson was developed as a portion of an entire unit of lessons focusing on food safety from farm to table. Use the following links to see the remaining lessons:

Module 1: Bacteria

Module 2: Farm

Module 3: Processing and Transportation

Module 4: Retail and Home

- Supermarket Smarts

- Cooking Right: The Science of Cooking a Hamburger

- A Chilling Investigation

- Crossed Up!

- Hands Off, Bacteria!

Module 5: Outbreak and Future Technology

Evaluation

Engage

- Set the stage for the activity by saying to the class: I have a mystery for you to solve. Together, we’re going to do some sleuthing! Here are two containers of juice.

- Do you see any differences between them? Remember, all science begins with awareness. What’s one way we become aware? (By making observations)

- How do we make observations? (Through the use of our senses. Mostly, we use sight. But sound, taste [although not in this case], and touch are also ways to make observations.)

- Can you determine which juice is safe to drink just by looking? Today, we’re going to do some detective work, and plan and carry out an investigation. Then you’ll report your findings to the class. It will be challenging! Let’s get started ...

Explore and Explain

Part 1: Design the Lab

Observe

- Assign students to work in teams of 3 or 4.

- Ask each team to record at least 5 observations about the juice. (Students may notice color and clarity differences. One juice may have some solids in it, etc.) You may wish to help them understand the difference between observation and inference before they start.

- Ask each team to share their best observations with the class. List them on the board.

- Ask the students what the different observations may mean.

Part 2: Develop a Hypothesis

- Develop a Hypothesis: Based on the class observations, challenge each team to come up with a hypothesis of which juice is pasteurized and which one is unpasteurized, and have them explain their reasoning.

Part 3: Solve The Mystery

- Now ask the students to solve the second part of the mystery by asking, "Which juice is safe to drink … and why?"

- Ask each team to design a lab to provide evidence for which juice is safe to drink. You may want to review pasteurization with the students. Students can use materials and equipment on the lab table.

- Challenge students to develop their experimental designs complete with a control (in this case, a standard of comparison).

- If your students come up with a variety of ways to determine which juice is safer to drink (pasteurized), that’s great. Go for it!

Part 4: Conduct the Lab

Option: Students can design a data table to record their results.

- Ask the students to review their experimental designs.

- Have teams carry out their labs.

- Note: You may need to show the students how to dip the sterile cotton swab into the juice and then inoculate the dishes (see page 2 of the Safety First in the Lab handout.)

Part 5: Collect, Organize, and Report Results

- Have teams observe the results of their lab and report their results to the class.

- Note: The unpasteurized juice should have a greater number of colonies when samples of both juices are plated on agar dishes.

- Together with the students, analyze the adequacy of the experimental designs. Ask students what they would do to improve their labs.

- Ask the students to relate their findings to food safety.

- Review how the students used the various pieces of equipment and how they designed their labs, complete with controls.

Elaborate

-

Research the history of pasteurization.

-

Answer the question raised in the video by Dr. Sizer, “How can you pasteurize an egg in the shell without cooking it?”

-

Research why some milk can be stored on the shelf and some milk must be refrigerated.

-

Write a letter to Louis Pasteur to thank him for developing the process of pasteurization, and tell him how important this process is in lowering the incidence of foodborne illness. Also explain how it makes foods more convenient for us today.

-

Research how people safely stored food prior to pasteurization, and choose which method you think was best — give reasons, specific details, anecdotes, and examples.

Evaluate

After completing these activities, review the following questions:

- Which juice would you prefer to drink, pasteurized or unpasteurized? Why?

- What effect would freezing have on microorganisms in unpasteurized juice? (Freezing does not kill bacteria. It only slows their growth.)

- How does pasteurization relate to your everyday life? (It keeps your food safe.)

- Can you tell if a food is pasteurized by looking at it? (No — you must read the product labels.)

Pasteurization is the process of destroying microorganisms that can cause disease. This is usually done by applying heat to a food. In order to determine which mystery juice is pasteurized, both must be plated on agar dishes and observed. The unpasteurized juice should have a greater number of organisms because it was freshly squeezed and may be contaminated from handling, etc. It hasn’t been heated to destroy bacteria.

Acknowledgements

The Science and Our Food Supply Curriculum was brought to you by the Food and Drug Administration Center for Food Safety and Applied Nutrition and the National Science Teaching Association.

- FDA Education Team Leader Food Safety Initiative: Marjorie L. Davidson

- FDA Science and Our Food Supply Project Director: Louise H. Dickerson

- FDA/NSTA Associate Executive Director and Science and Our Food Supply Program Director: Christina Gorski

- FDA/NSTA Science and Our Food Supply Program Assistant: Jill Heywood

Recommended Companion Resources

Author

Organization

| We welcome your feedback! If you have a question about this lesson or would like to report a broken link, please send us an email at [email protected]. If you have used this lesson and are willing to share your experience, we will provide you with a coupon code for 10% off your next purchase at AgClassroomStore. |